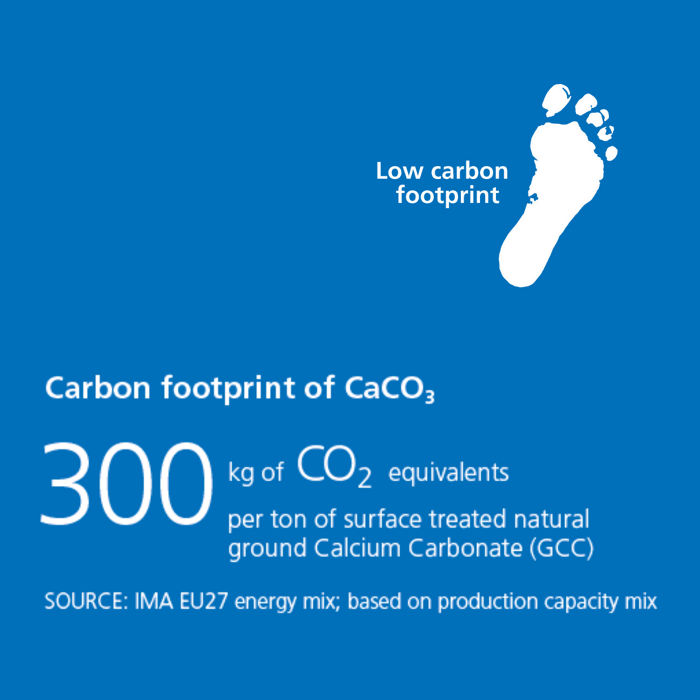

Omyafiber is an innovative mineral solution that enables fibers and nonwovens producers to reduce their carbon footprint and raw material costs whilst enhancing product properties.

It is a high purity, calcium carbonate enriched with Omya exclusive proprietary treatment for polypropylene (PP), polylactic acid (PLA) and polyester (PET) fibers and nonwovens.