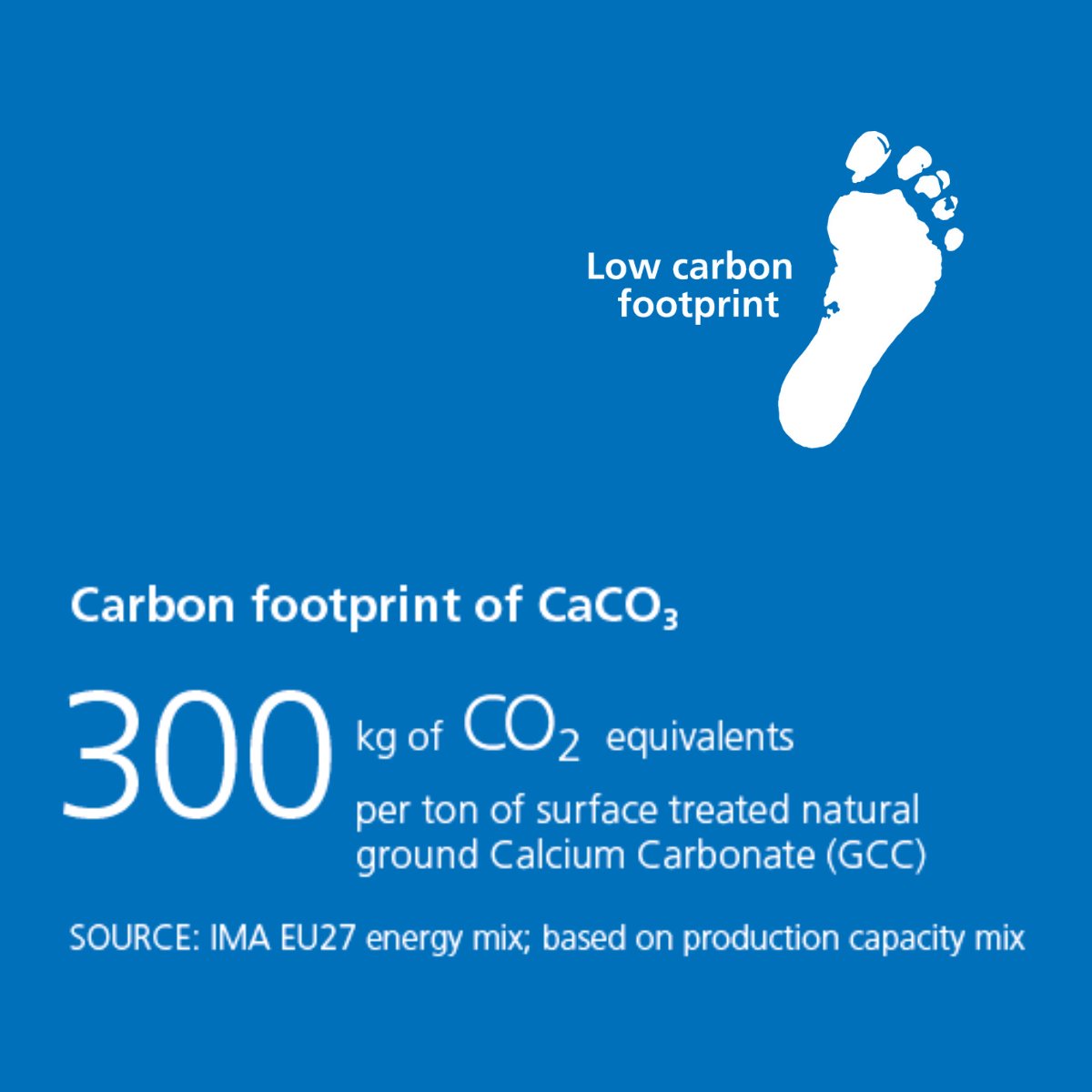

The inclusion of calcium carbonate as a functional mineral in polymer products has a significant impact on both their performance and the carbon footprint of the final product.

From breathable films for improved user comfort to lower cost nonwoven fabrics with better tactile properties and engineered polymers with greater thermal resistance, Omya solutions consistently deliver better results for customers.

_mirrored%20to%20left?qlt=85&ts=1714124493833&dpr=off)