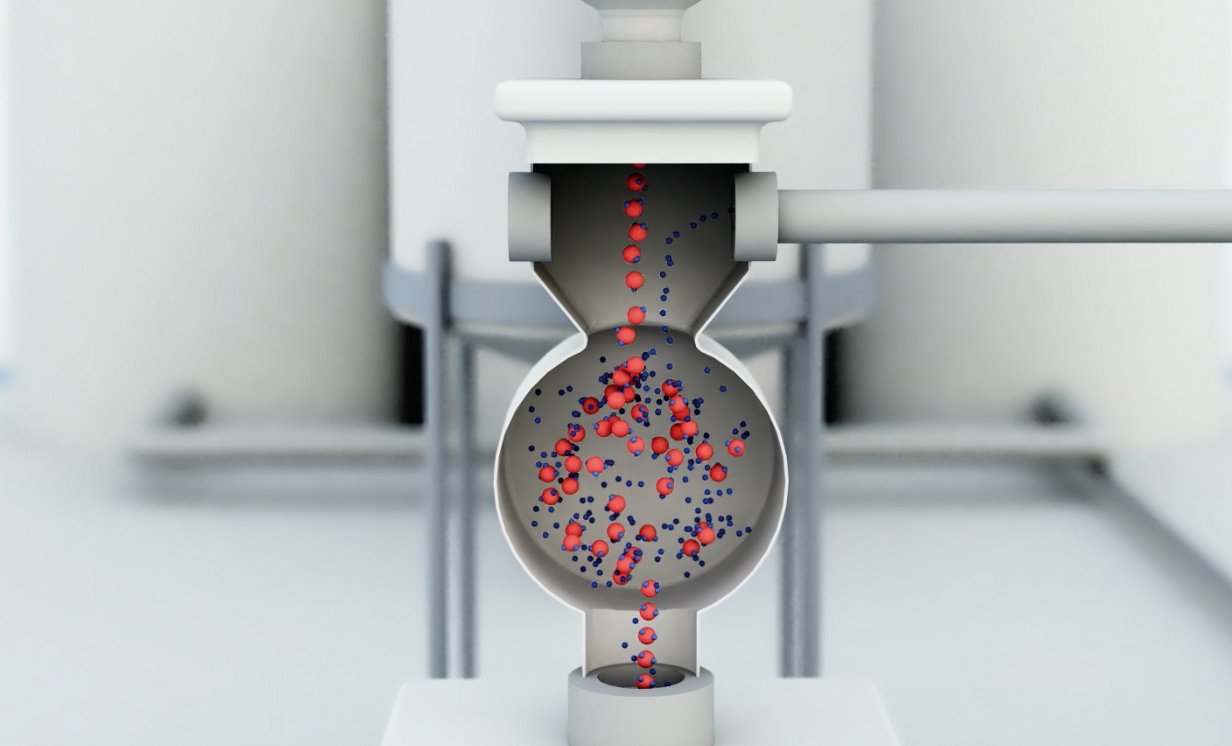

Omya's solutions for pipe manufacturing offer a comprehensive approach to improving product quality, exceed limitations in mineral loading and increase production efficiency.

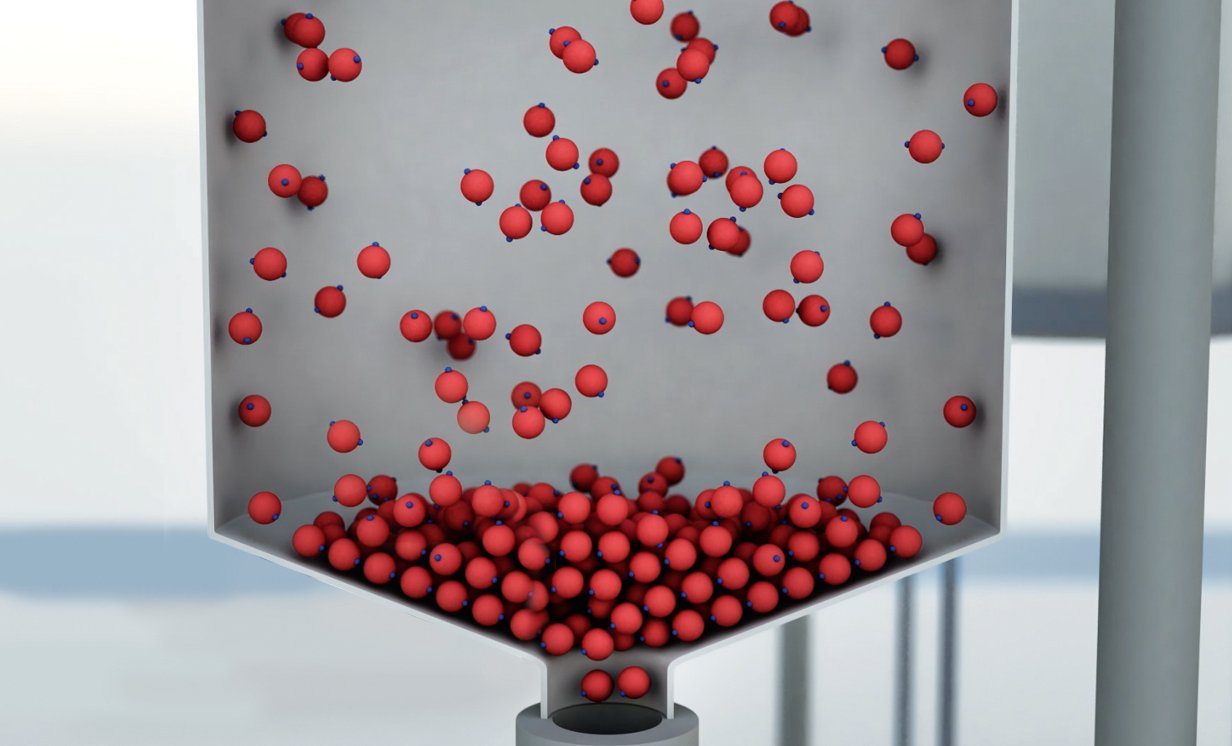

The Omyacarb line of treated calcium carbonate products can be used to optimize the formulation and lower the total material costs of pipe production. The Omyalene product family, consisting of highly filled masterbatches, offers a solution for enhancing the mechanical properties of polyolefin-based non-pressure pipes.